Post-repair safety inspections are crucial for vehicle dent repair and restoration, ensuring compliance with OEM standards. Skilled technicians use specialized tools to meticulously check welds, paint, and structural components, verifying quality against manufacturer specifications. These inspections prioritize customer satisfaction and road safety by identifying and rectifying subpar work, adhering to guidelines that encompass structural integrity, safety systems, and aesthetic precision. Best practices include tailored checklists, advanced tools, and regular training.

Post-repair safety inspections are vital steps in ensuring vehicles meet Original Equipment Manufacturer (OEM) standards. This comprehensive process aligns with industry best practices, guaranteeing vehicle safety and reliability after repair or maintenance. Understanding the procedures and OEM requirements is essential for workshops to deliver high-quality services. By adhering to effective inspection protocols, garages can maintain customer trust, prevent potential hazards, and uphold their reputation in a competitive market.

- Understanding Post-Repair Safety Inspection Procedures

- OEM Standards: Key Components and Requirements

- Ensuring Compliance: Best Practices for Effective Inspections

Understanding Post-Repair Safety Inspection Procedures

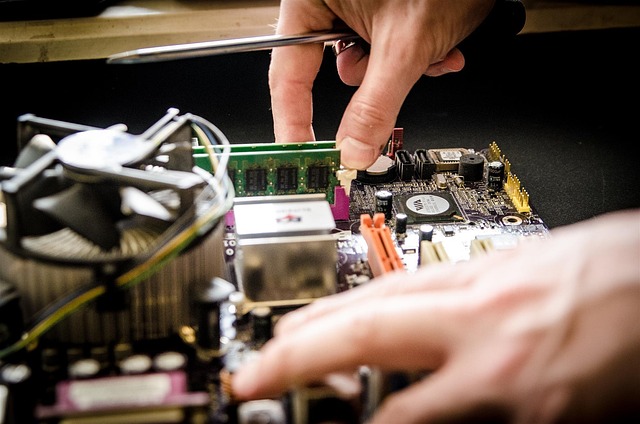

Post-repair safety inspection procedures are a crucial step in ensuring that every vehicle dent repair or car restoration service meets Original Equipment Manufacturer (OEM) standards. These inspections involve a thorough evaluation of the repaired area, aiming to verify structural integrity and adherence to safety regulations. It’s not just about visually inspecting for dents; it encompasses checking welds, paint jobs, and other components to ensure they meet the exacting standards set by vehicle manufacturers.

In a vehicle body shop, this process is meticulous and detailed-oriented. Technicians use specialized tools and techniques to assess the quality of the repair work. From ensuring proper alignment of panels to verifying the strength of replacement parts, every aspect is scrutinized. This not only guarantees customer satisfaction but also promotes safety on the road, as vehicles with subpar repairs can pose significant risks during operation.

OEM Standards: Key Components and Requirements

OEM standards are the gold standard for automotive manufacturing, outlining precise specifications and requirements for every component that goes into a vehicle. When it comes to post-repair safety inspections, these standards serve as a crucial reference point. Key components of OEM standards include structural integrity, safety systems, and aesthetic accuracy. For instance, in the case of frame straightening and vehicle paint repair, OEMs dictate specific tolerances, ensuring the restored vehicle matches the original manufacturer’s design.

These guidelines are vital for auto body services, as they guarantee that post-repair vehicles meet the highest safety standards. Every aspect, from aligning panels to repainting, must adhere to these stringent requirements. A thorough post-repair safety inspection is not just a best practice; it’s an essential step to ensure customer safety and satisfaction, confirming that every vehicle leaves the workshop in as good or better condition than it entered.

Ensuring Compliance: Best Practices for Effective Inspections

A post-repair safety inspection is a critical step to ensure that vehicles meet Original Equipment Manufacturer (OEM) standards after any repair work, be it car paint repair, vehicle bodywork restoration, or auto glass replacement. This process involves meticulous checks on various components, including structural integrity, functionality, and aesthetic accuracy, to guarantee the vehicle’s overall safety and performance.

Best practices for effective post-repair safety inspections include a comprehensive checklist tailored to specific vehicle models and repair types. Inspectors should verify that all repairs align with OEM guidelines, utilizing advanced tools and technology to assess precision and quality. Moreover, regular training sessions and knowledge updates are essential for inspectors to stay current with industry standards and emerging best practices, ensuring consistent and accurate assessments across different car paint repair, vehicle bodywork, and auto glass repair scenarios.

Post-repair safety inspections are a critical step in ensuring vehicles meet Original Equipment Manufacturer (OEM) standards. By aligning with these standards, repairs maintain structural integrity and performance, enhancing road safety. Implementing best practices for effective inspections, as outlined in this article, helps garages stay compliant, uphold vehicle quality, and satisfy customer expectations. Regular post-repair safety checks are not just a regulatory requirement; they are a cornerstone of reliable and safe automotive maintenance.